Manufacturing Capabilities

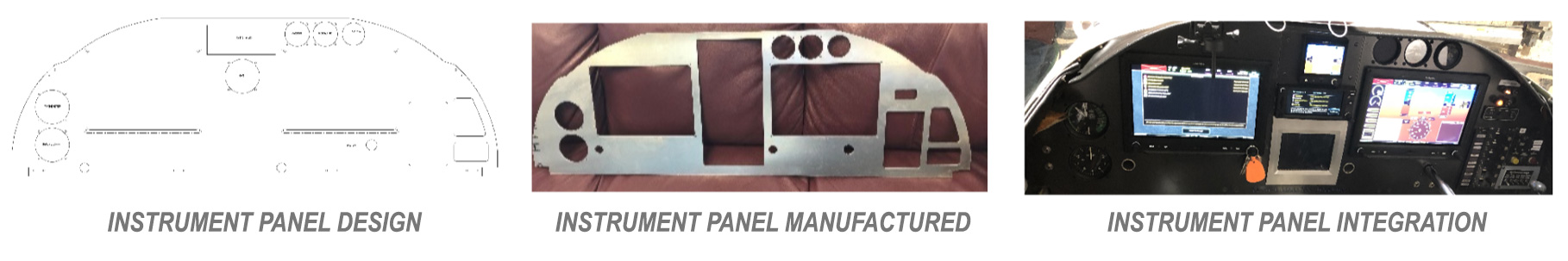

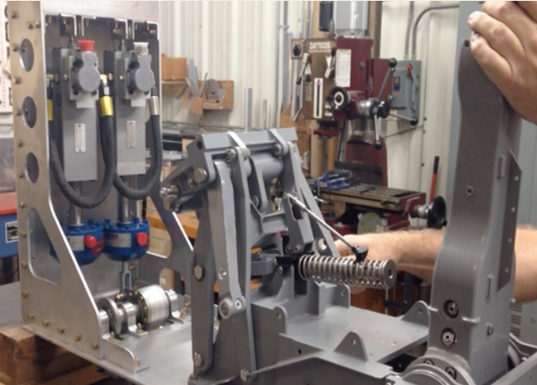

All Flight Level Engineering products are designed, manufactured and assembled in-house. Designs are created using SolidWorks® CAD software. Many of the components we build are used on board our in-flight simulation research aircraft. This same uncompromising attention to detail is applied across the board to all our products. Flight Level Engineering’s quality management procedures meet or exceed those set by ISO 9001 standards. Each assembly in our simulators is thoroughly documented with strict configuration management and like our aircraft products, each part is assembled by an FAA licensed A&P mechanic.

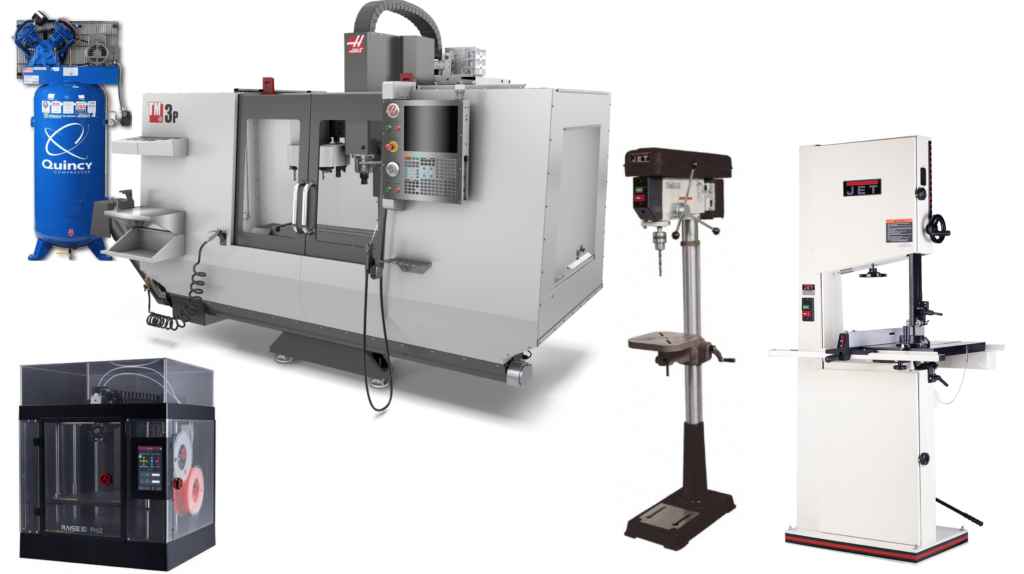

If you want a job done right and, on your schedule, you better do it yourself. Flight Level Engineering has the right tools for the job. In addition to our impressive suite of software tools, Flight Level Engineering has a full in-house machine and composite shop featuring a state of the art Haas 3-Axis CNC vertical mill.

Core Manufacturing Capabilities:

- 3-axis CNC Milling

- Additive Manufacturing / Rapid Prototyping ; Production-grade thermoplastic

- Advanced Composite Fabrication

- Plug and Tooling

- Powder Coat / Finishing

- Assembly/Integration

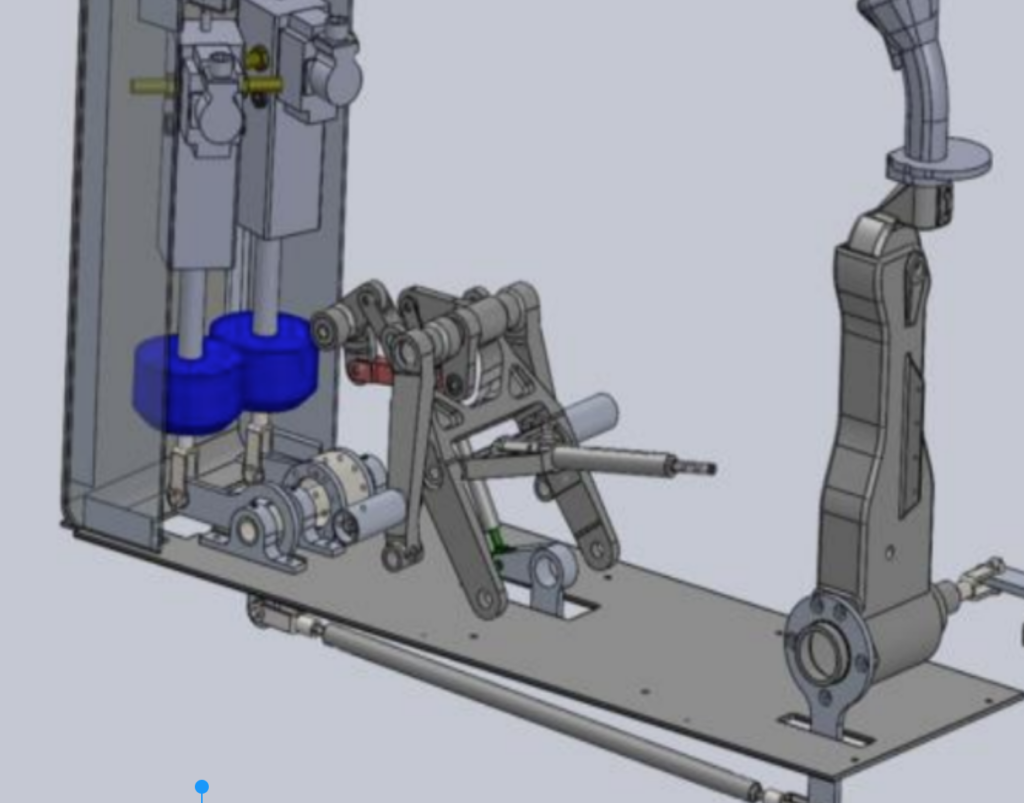

Complex Mechanical Design

Final Assembly

Portable Ground Simulator Design

Portable Ground Simulator Finished Product